ABOUT

Nantong Hongshun Cookware Products Co., Ltd.

Founded in 1993, it is a Sino-foreign joint venture, specializing in the production of tempered glass covers.

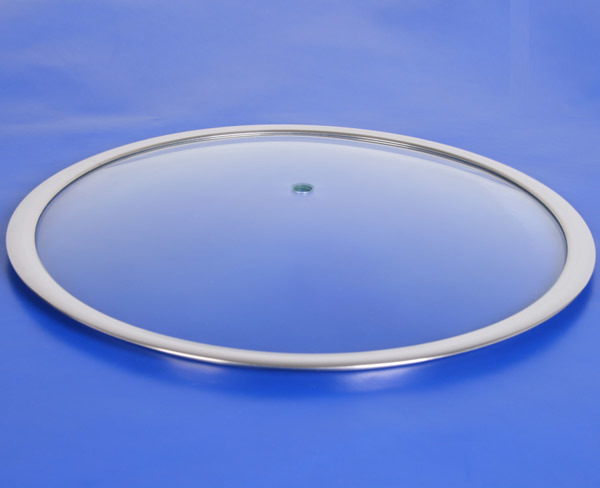

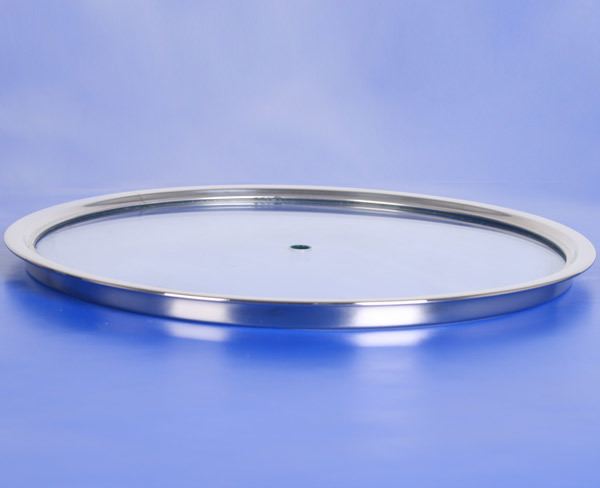

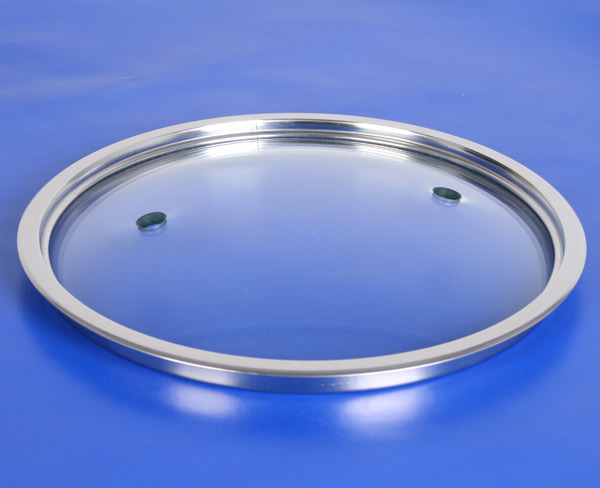

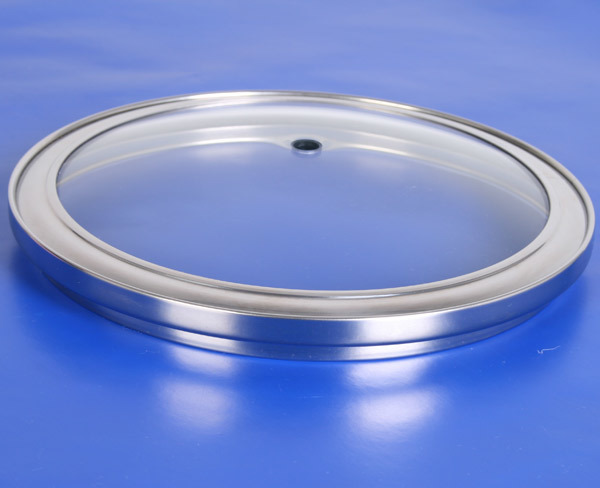

Nantong Hongshun Cookware Products Co., Ltd. was established in 1993 as a Sino-foreign joint venture. Specializing in the production of tempered glass covers. There are 260 employees (including 36 professional and technical management talents who have graduated from universities and colleges). Covering an area of 30,600 square meters, the effective plant area is over 21,000 square meters. The registered capital is 3 million US dollars. Fixed assets of more than 36 million yuan. Our company focuses on technological transformation and continuous innovation. There are currently eight internationally advanced production lines for tempered glass covers. The annual production capacity reaches 30 million pieces of glass covers.

Our company was founded in 1993

More than 260 employees in the company

Annual production capacity of 30 million pieces

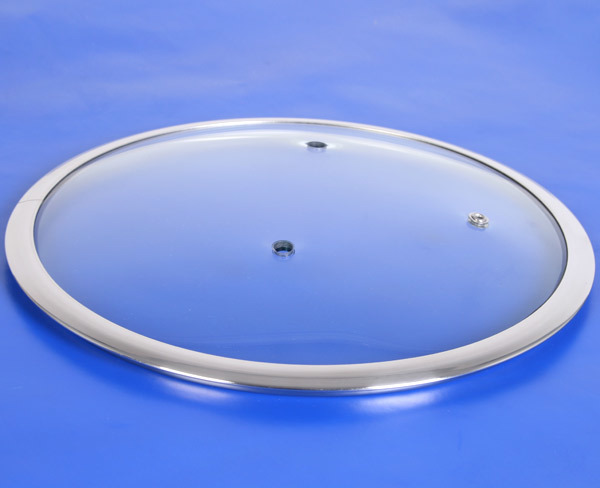

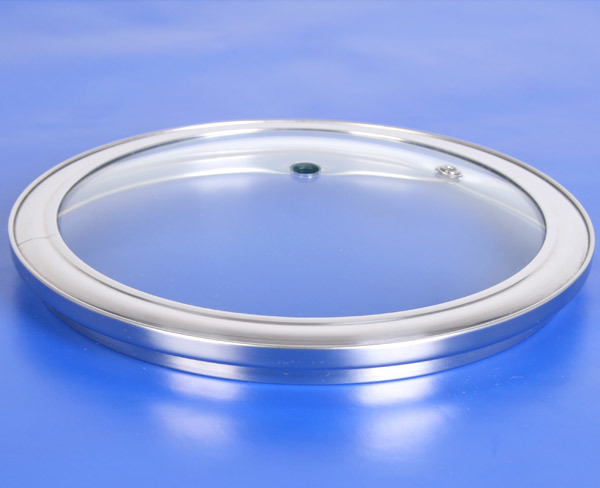

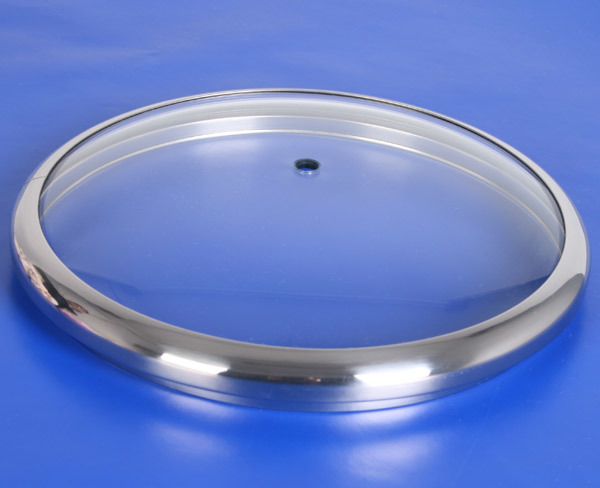

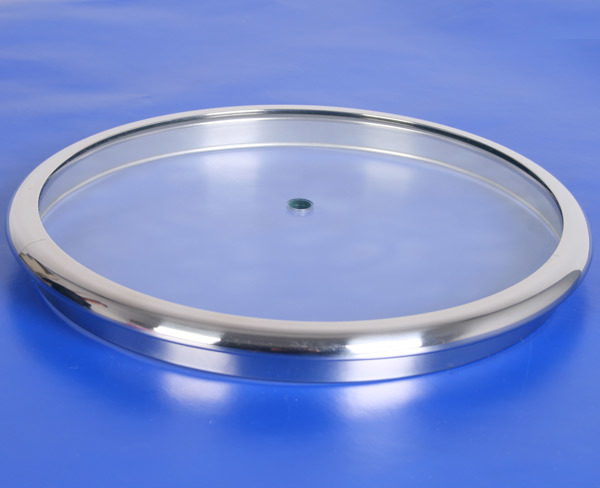

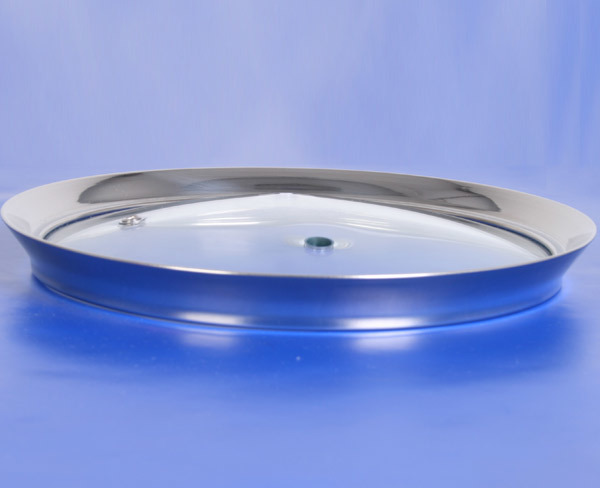

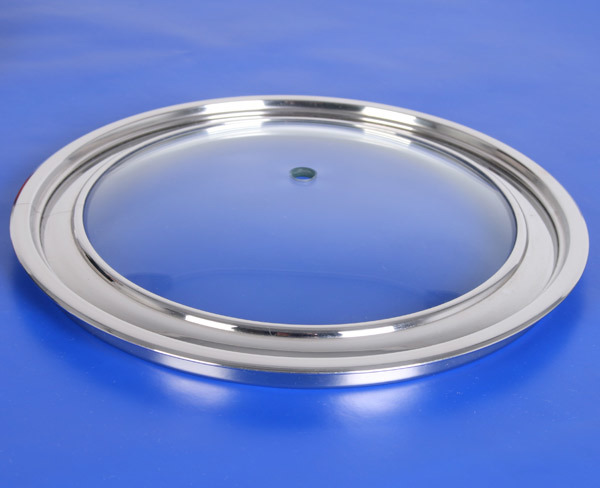

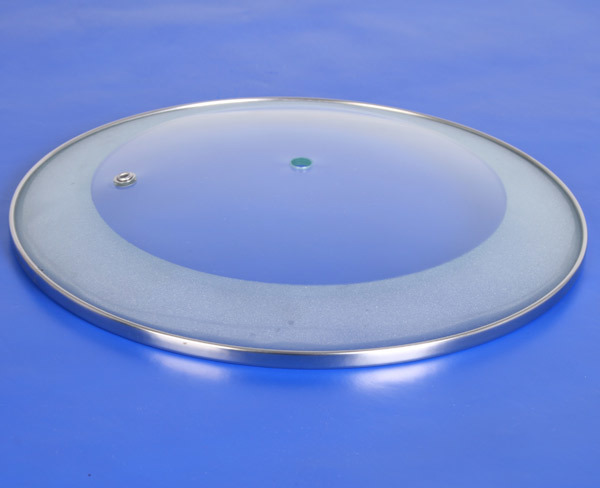

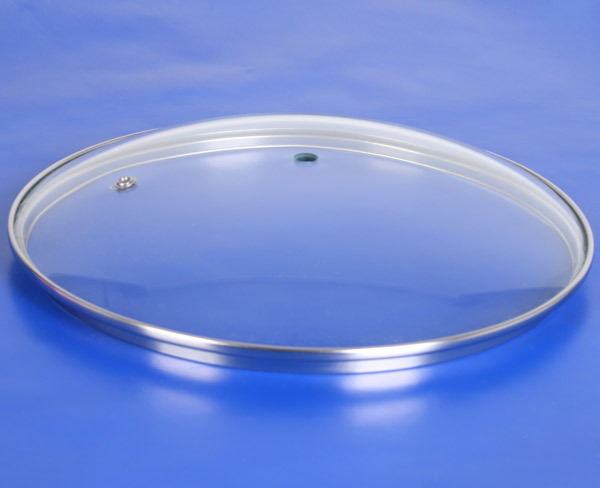

Products

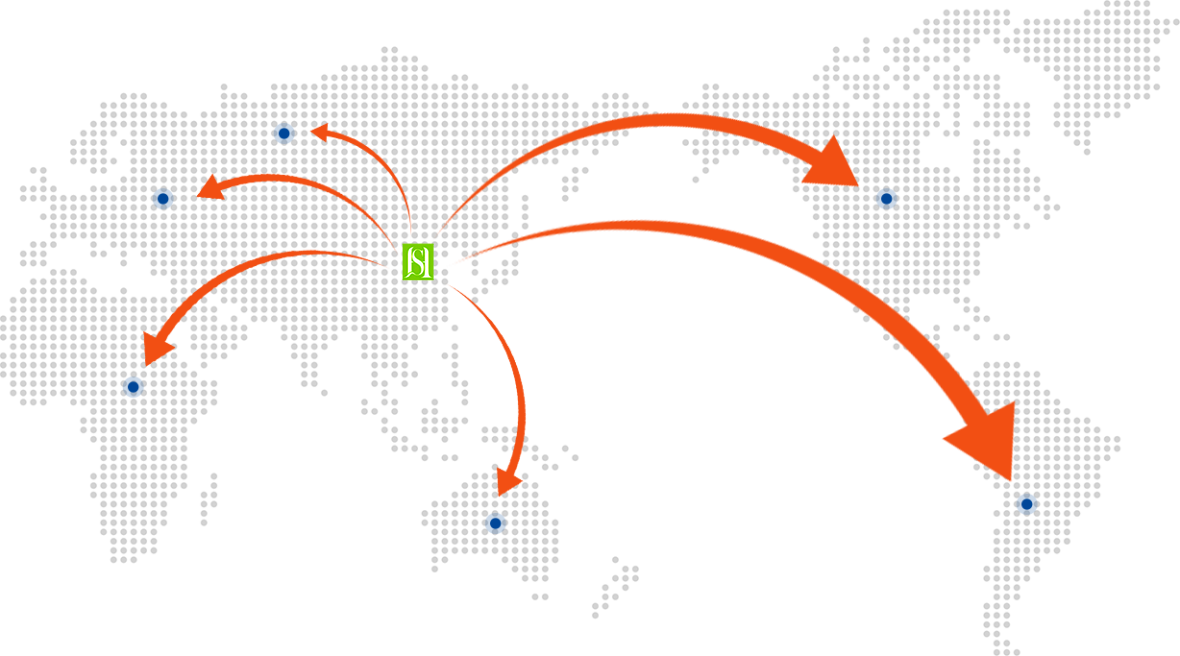

Sales network

Our products are mainly sold to the United States, the United Kingdom, France, Germany, Switzerland, Brazil, Italy, Turkey, Belgium and other European and American countries, and also to Japan, South Korea, Pakistan, Russia, India and other Asian countries, and are deeply loved by domestic and foreign customers. .

Create high-quality products and provide honest services

Specializing in the production of tempered glass covers, focusing on technological transformation and continuous innovation, there are currently eight internationally advanced production lines for tempered glass covers. The annual production capacity reaches 30 million pieces of glass covers.

NEWS CENTER

2022-09-26

The difference between tempered glass and tempered glass

The difference between tempered glass and tempered glass lies in the difference in strength and performance. Tempered glass refers to tempered glass, which has good mechanical properties and thermal shock resistance; while tempered glass refers to flat glass that has been tempered by flame and has high compression resistance. The strength of tempered glass is not very good, it is easy to break, and the fragments are easy to hurt people. The strength of tempered glass is very good. It is a kind of glass that has been strengthened and is not easy to break. Even if it is accidentally broken, the fragments are all connected together. Generally speaking, tempered glass is better than semi-tempered glass, and tempered glass is basically used in daily households.

view more

2022-09-26

Strengthening principle and process flow of chemically strengthened glass

Chemically tempered glass is mainly made of glass with a thickness of less than 3mm. It is heated to about 420 degrees Celsius with a high-purity potassium nitrate solution and a matching catalyst. The potassium ions and sodium ions on the surface of the glass structure undergo ion exchange to form a strengthening layer. Due to the slow exchange rate of potassium and sodium ions, in order to make the glass have a large stress value and a thickness of the stress layer that meets the requirements of use, the exchange time varies from 4 hours to 10 hours. The depth of the compressive stress layer of chemically tempered glass generally ranges from 5um to 25um, but Corning's Gorilla Glass and AGC's Dragon Trace Glass can increase the stress layer to 50um. The bending strength can reach 600-800mpa. White sheet finished product—QC inspection—cleaning treatment—chemical strengthening—insulation and cooling—cleaning and drying—packaging. Main test methods for the strength of chemically strengthened glass a, flexural strength of glass (CL) b, impact strength of glass (CT) c, depth of compressive stress layer of glass (DOL) Method 1. Impact strength test of glass with steel ball - falling ball crushability test Method 2, static pressure test method. Use the thimble to increase the pressure at the center of the glass until the pressure value at the moment when the glass is broken. Method 3. Compressive stress layer depth test method---quantitatively measure the glass surface with a compressive stress tester, and calculate the pressure layer depth on the glass surface.

view more

2022-09-26

Tempered glass is obtained by first cutting ordinary annealed glass to the required size, then heating it to about 700 degrees close to the softening point, and then rapidly and uniformly cooling it (usually 5-6MM glass is heated at a high temperature of 700 degrees for about 240 seconds, Cool down for about 150 seconds. 8-10MM glass is heated at a high temperature of 700 degrees for about 500 seconds, and cooled for about 300 seconds. In short, according to the thickness of the glass, the time for heating and cooling is also different). After tempering, uniform compressive stress is formed on the surface of the glass, while tensile stress is formed inside, which improves the bending and impact strength of the glass, and its strength is about four times that of ordinary annealed glass. The tempered glass that has been tempered cannot be cut, ground, etc. or damaged, otherwise it will be "shattered" due to the destruction of the uniform compressive stress balance.

view more